Products

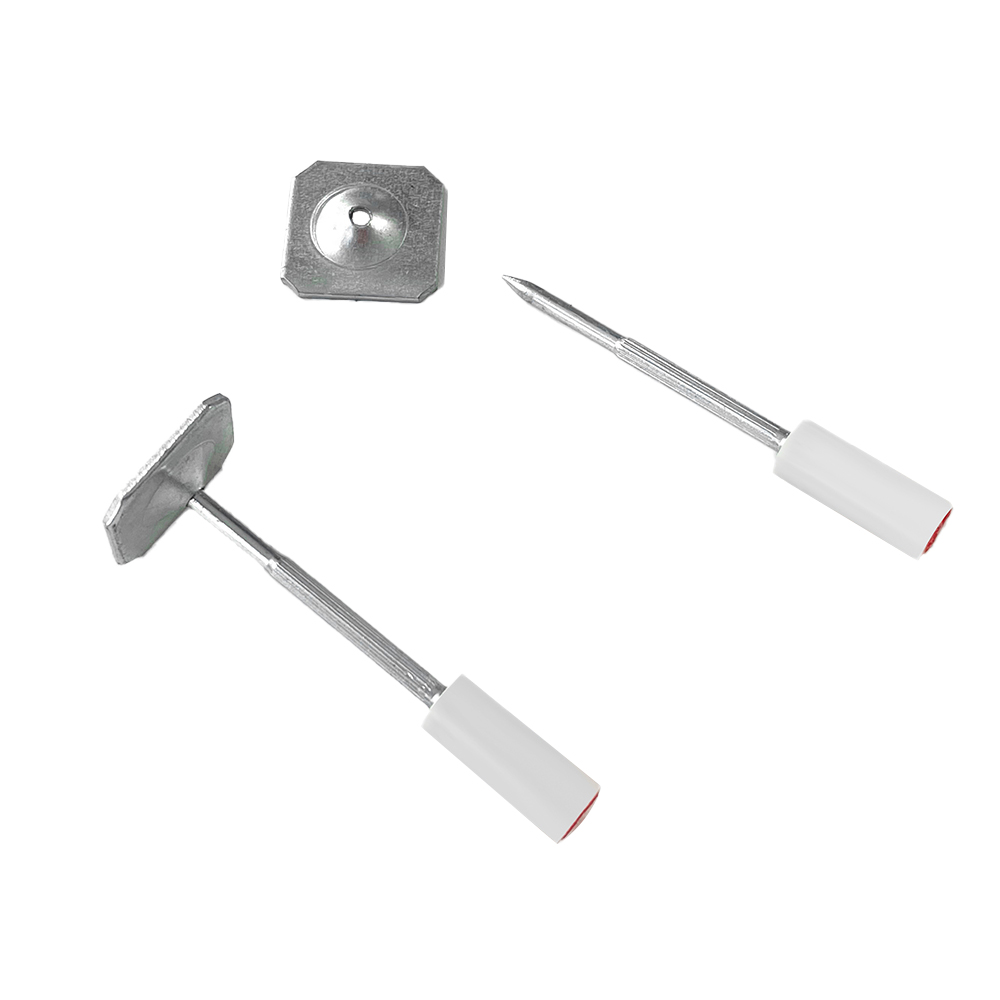

Nitrocellulose Integrated Powder Actuated 16mm Piping Nails for Construction

Feature

1. High hardness.

2.Strong penetration.

3.2mm thickness material.

4.Hot galvanizing surface.

5.Good stability and safety.

The integrated piping nail adopts an innovative design, which cleverly integrates the energy part and the nail part, making it more portable to use. The pipe clamp integrated nail has the characteristics of structural stability which ensures that the pipe nail will not loosen or break during use, thus guarantee the safety and reliability of construction work. The pipe clamp integrated nail has an excellent service life because the piping nail resists corrosion and wear in harsh environments. Therefore, users can safely use the integrated nail without frequent replacement or repair, thereby reducing maintenance costs and the risk of work delays. Users can select and use the integrated piping nails to improve work efficiency and safety.

Product Parameters

1.Use a steel sheet with a thickness of 2mm, and the thickness of the coating is not less than 5μ.

2.When shooting C30-C40 concrete, drawing capacity within 4200-5800N2. Different intensity of concrete affects different depth of pipe nails which leads to different data. We use a safe range of data. Usually, the drawing force of single nail suites for load less than 100kg.

3.Types of pipe clamp: G16.

Application

The pipe clamp is widely used to install wire, pipes and electricity.

Special Design

Double base propellant, more safe than single or so-called multi propellant. The power part of the integrated ceiling nail is made with nitrocotton and nitroglycerin or other explosive plasticizers as its basic energy component. Generally used for large caliber artillery and mortar firing charges.